This product is suitable for the baking process of pouch cell and aluminum shell battery electrode, with programmable automatic control, 7-inch color large screen for setting process parameters and man-machine dialogue. This product has the characteristics of large volume, double circulation of heat source, ultra-high vacuum degree, intelligent control, etc. It brings the benefits of shortening the process time and improving the production capacity of the whole line for the baking of electrode. It is an essential production equipment for power lithium ion cell enterprises in the new era

Heating method: Heating plate contact heating.

Vacuum method:

Vacuum baking: During vacuum baking, the vacuum valve is opened to continue vacuuming, and after the vacuum baking time is reached, the vacuum valve is closed;

Nitrogen heating: During the heating period, the air in the working chamber is replaced, and the nitrogen heating starts;

Vacuum pressure holding: After the cycle is over, select the vacuum pressure holding function, the vacuum valve will open, and when the vacuum reaches -101Kpa, the vacuum valve will close; if the rapid cooling function is selected, when the rapid cooling reaches the set temperature, the vacuum valve will open, and the vacuum will reach -101Kpa The vacuum valve will close when the vacuum reaches - 101Kpa.

Nitrogen filling method:

Nitrogen filling implements the "intermittent" filling mode. The internal wind disturbs the nitrogen flow and quickly penetrates into the cavity. When the nitrogen setting value is reached, the valve is closed to prevent nitrogen overshoot.

Cooling method: Transitional cooling.

Embedded installation:

The color steel plate wall inlay position and sealing position are reserved for the box body.

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

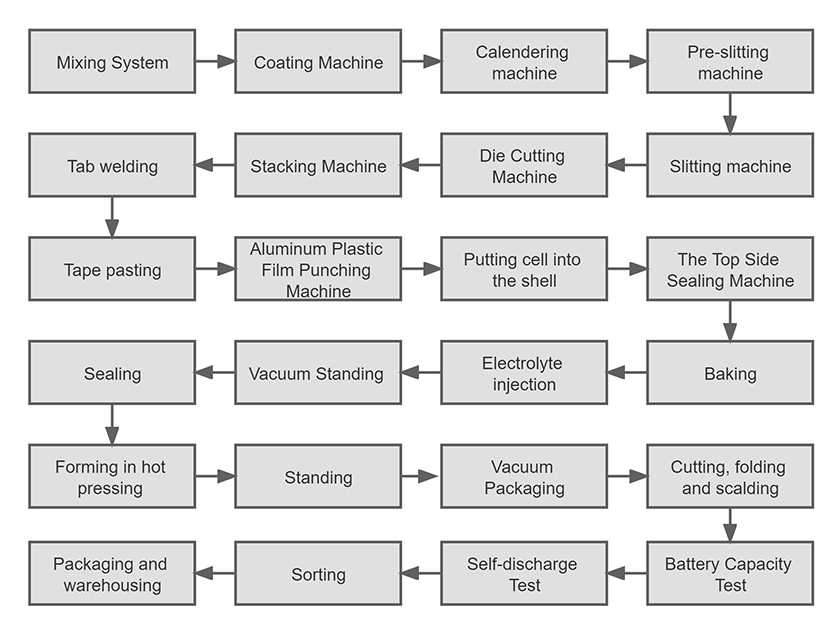

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat