The pole piece base material placed on the unwinding device enters the unwinding tension system after automatic deviation correction, and enters the first surface coating mechanism after adjusting the unwinding tension. Coating is carried out according to the set procedure, and the slurry is driven by the rotation of the coating roller. The amount of slurry transferred is adjusted by the comma scraper gap, and the slurry is transferred to the substrate by the rotation of the back roller and the coating roller; the wet pole piece coated on the first side enters the lower oven to be dried by hot air; the first side The dried polar piece is rectified by the deviation correcting system, and then the tension is adjusted by the tension system, so that the coating speed of the first side and the second side are synchronized. Drying, the dried pole piece is corrected by the deviation correction system, and reaches the traction and winding mechanism through the transition frame, and is wound by the winding device.

Product advantages:

1, Can be coated on both sides without stopping the machine to change rolls.

2, The steel roller, rubber roller and scraper have a simple installation structure and are easy to repair and maintain.

3, The control system is simple and convenient to operate, and the touch screen interface is simple and easy to understand.

4, With head and tail thickness adjustment function, automatic closed-loop adjustment of scraper gap, closed-loop tension control system coating length measurement function (optional), front and back alignment system, oven over-temperature protection system, online defect inspection system (optional).

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

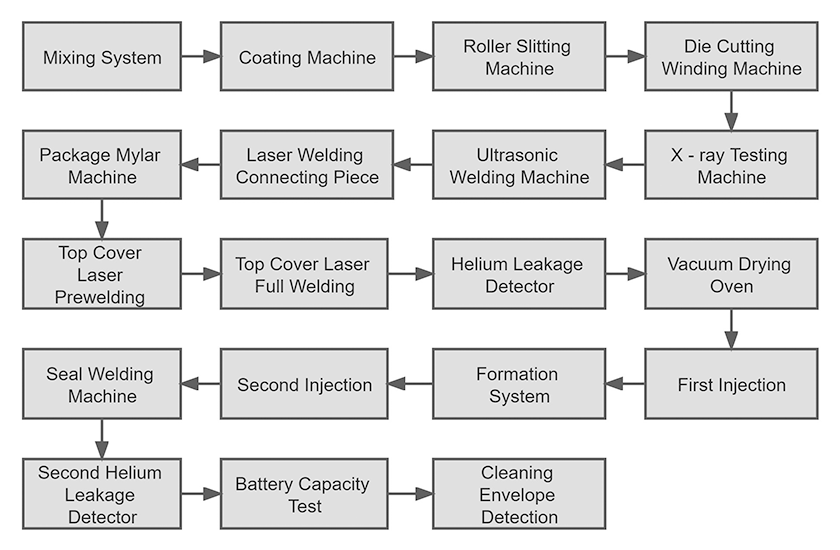

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat