Production capacity:PPM≥6 or 12

Control mode :PLC+ MES

Power supply:AC380v/ 3-triphase/ 50Hz

Operating pressure:0.5-0.7Mpa

Actuators type:cylinder, Servo

Vacuum degree:-90 -97kp

Production yield:99.8%

Airtightness: 50Pa

Filling pressure: 0.1 ~ 0.3MPa

Filling time: 6-15min

Equipment size :7000mm*5900mm*2300mm

This machine automates the electrolyte filling process for prismatic lithium batteries.

Production capacity:PPM≥6 or 12

Control mode :PLC+ MES

Power supply:AC380v/ 3-triphase/ 50Hz

Operating pressure:0.5-0.7Mpa

Actuators type:cylinder, Servo

Vacuum degree:-90 -97kp

Production yield:99.8%

Airtightness: 50Pa

Filling pressure: 0.1 ~ 0.3MPa

Filling time: 6-15min

Equipment size :7000mm*5900mm*2300mm

This machine completely automates the electrolyte filling process for lithium batteries manufacturing. As the battery is loaded to the machine from the conveyor it is weighed and its barcode is scanned. Before the battery is filled with the electrolyte its electrical insulation is verified with an Hi-pot test.

The cell is first degassed to reduce the amount of gas within the porous electrode foils and to speed up the filing process, then it is filled with the electrolyte and left to stand, so that the wetting of the battery cell takes place.This process is repeated several times until the battery is completely full. Once the battery is filled, the filling opening is automatically cleaned and sealed.

All data processed during the filling process such as the vacuum degree,weight etc. is linked to the barcode on the top of the battery and is automatically stored on the computer unit where it is uploaded to the MES system.

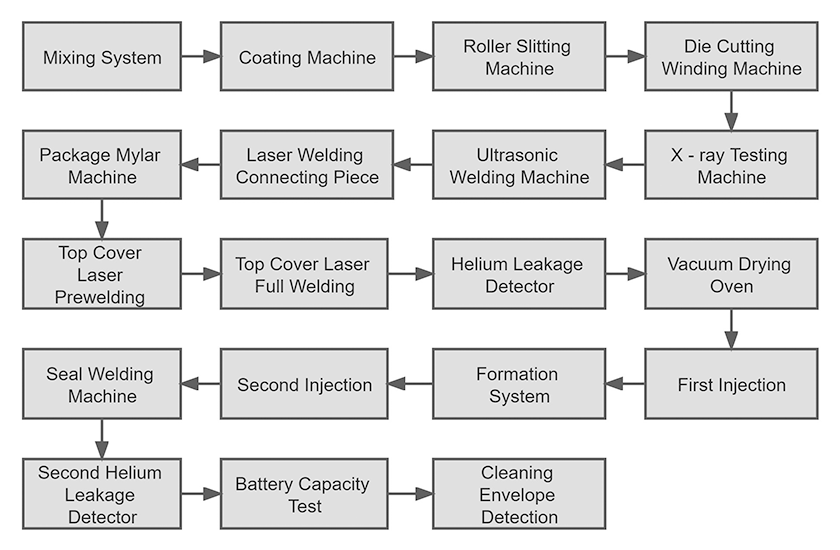

Process flowchart:

Safety: this machine is equipped with multiple emergency buttons, visual and acoustic warning, and safety sensors i.e.light curtains to comply with China equipment's safety standards.

Robustness: failure rate 2%.

Operability: machine commands are easy to understand and training is provided.

Flexibility: components are quick and easy to replace, the equipment can be adjusted to handle batteries with different dimensions by only replacing few parts, smart design allows to minimize wearing parts and make the maintenance process easier.

Machine output: PPM 6 or 12.

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat