Eight adsorption boxes phased liquid injection machine

Applicable battery model: 18650, 14500 and other cylindrical batteries (can be customized according to the model provided by the customer, or can be shared by multiple models, just replace the tray).

Equipment production capacity: 50,000~80,000 pcs per 10 hours per shift (refer to battery model 18650, capacity 2000mAh), the liquid injection speed is determined by the battery capacity.

Liquid injection process: first point the cap and then inject liquid;

Electric pump injection pump injection accuracy: ±0.02g; (actual accuracy after battery injection is completed: ±0.1g);

Liquid injection manipulator displacement accuracy: ±0.05mm;

Vacuum adsorption box: 8 sets, the vacuum and pressure can be set arbitrarily between -0.095~0.45Mpa according to the process requirements and the actual working situation;

Compressed air: 0.5~0.8Mpa;

Vacuum: -0.085~-0.092 Mpa (provided by the buyer);

Dry gas (nitrogen): working pressure 0.4Mpa ~0.5Mpa

Equipment utilization rate: >95%;

Equipment qualified rate: >98%;

General configuration of the glove box:

1. One side is equipped with 14 stations;

2. A set of 8 vacuum percolation tank segmented automatic liquid injection machines (the percolation tank is formed at one time, and positive pressure can be added to 0.45Mpa);

3. Two sets of automatic liquid supply systems;

4. 5 sets of 4-head injection pumps;

5. Equipment dimensions: 13.2 m * 1.2 m * 1.8 m (length * width * height);

6. Sealing performance: no leakage, the connection parts of the glove box are guaranteed not to be glued, and all of them are fully welded or sealed;

7. Compressed air: 0.5~0.8Mpa;

8. Dry gas (nitrogen): working pressure 0.4Mpa ~0.5Mpa;

9. Dew point: - (35~45) (determined by the dehumidification unit).

Dehumidification Units:

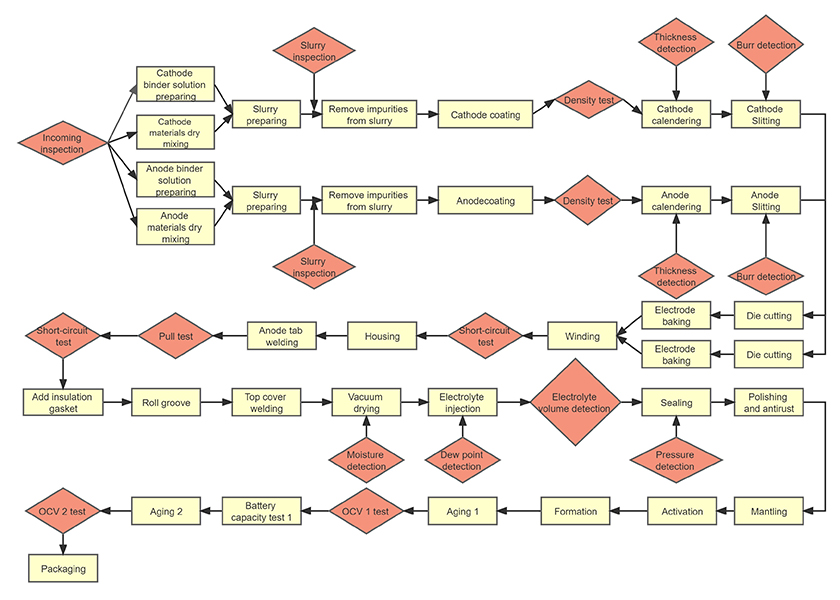

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat