It is mainly used for continuous automatic shell forming and automatic cutting of flexible packaging lithium battery cell packaging film, and automatically flows into the receiving trough after cutting.

Process flow:

The equipment adopts the structural form of automatic unwinding of rolls, servo feeding, servo stretching, and fixed-length cutting. The rolls are continuously formed and cut into monomers to realize automatic production.

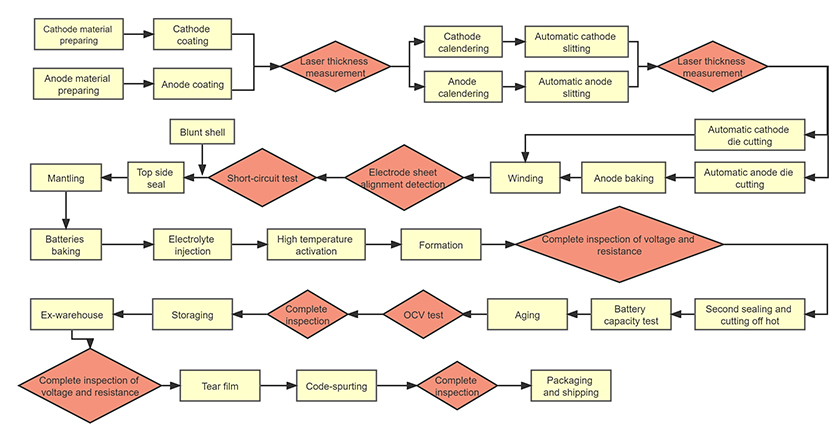

Flow chart:

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat