This equipment can be widely used for battery electrode sheet baking, cell winding baking and battery baking.

Adopting the most advanced dual heat source and double cycle technology, intelligent process control and problem tracing function, it has outstanding performance in high temperature uniform temperature, pressure maintaining, heating and cooling speed, etc., shortens the baking cycle, saves energy and electricity by 1/3.

Features:

1. Patented structure of double heat source and double circulation: internal circulation for heating, external circulation for heat preservation and precise temperature control.

2. Multiple devices can be controlled centrally, and the touch screen can display the working status; PLC control, stable and reliable.

3. It has temperature curve and record query, and the action of each valve body is under closed-loop.

4. With pressure curve and record query, fault alarm display.

5. Touch screen centralized operation and setting, abnormal active alarm display.

6. The equipment has the function of hierarchical management of personnel, including the password of the operator and the password of the administrator; a serial port for computer communication is reserved.

7.Double circulation internal and external channels: there are circulation channels inside and outside the oven chamber - the internal circulation heats up when the dry gas inside, and the external circulation keeps warm when inside is vacuum. Make the heating up faster and the temperature more uniform.

8. High vacuum pneumatic baffle valve to achieve 200 Pa high vacuum.

9. Elastic double-layer doors, digital pressure detection, and over-voltage protection.

10. Five safety protections, three-position temperature control, PID adjustment, small thermal inertia and good temperature control effect.

11. The total baking time, cycle time, vacuuming time and drying time can be set. After the parameters are set, you can click the automatic button to enter the automatic baking program.

1 2. There are input (operation) error self-locking and display.

13. The vacuum tube is anti-corrosion.

1 4. Program interlocking prevents interlayer gas transmission.

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

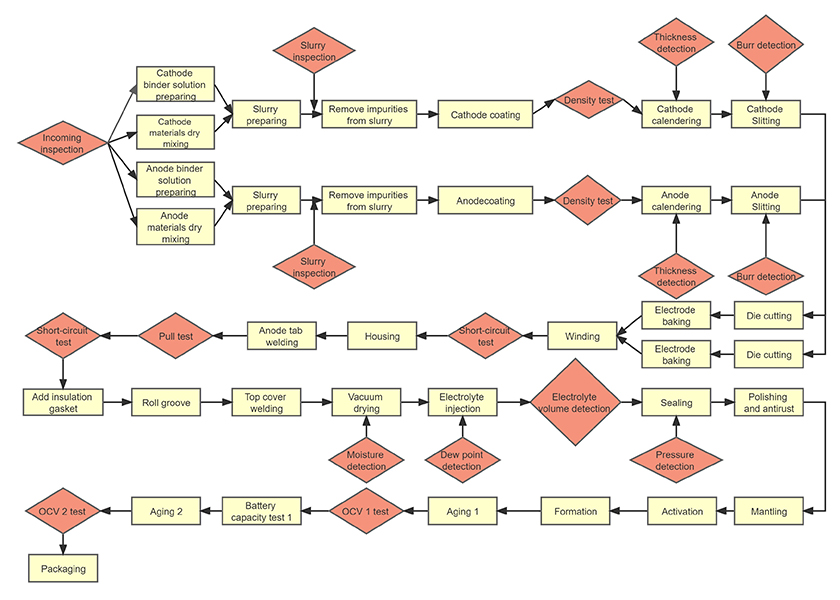

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat