Application Brief:

One set of imaging system, two sets of manipulator online detection and analysis are used for online full-automatic detection of square polymer pouch cells or finished batteries. The equipment emits X -rays through the X-ray generator and penetrates the inside of the battery. The imaging system receives the X –rays, images and takes pictures. The image is processed by relevant software and automatically measured and judged to determine the good and bad products. The bad products are selected. The front and rear ends of the equipment can be connected with the production line.

Feature of Product:

The software is rich in functions: 1. Automatically measure the alignment of the cathode and anode plates of the battery, and count the maximum, minimum, average, cathode and anode overhang; 2. Automatically judge the good and bad products, and automatically sort defective products; 3 . Scan the code function, record the battery code, track the battery test results one by one and upload them to the terminal server.

High detection efficiency: a set of imaging system and two sets of feeding manipulators operate alternately to realize online detection and analysis. The efficiency is high, and the daily inspection of square polymer pouch cells or finished batteries in large quantities.

Production line connection: the material inlet and outlet can be connected with the production line.

Fast changeover and commissioning: the changeover and commissioning of different types of batteries are fast, and the replacement time is within 10-30min.

Safety and environmental protection: the whole equipment is safe and interlocked, with triple protection functions, and any part of the fuselage surface meets safety radiation standards.

Detection object:

Check the alignment of the square polymer pouch batteries and cathodes and anodes of the finished battery.

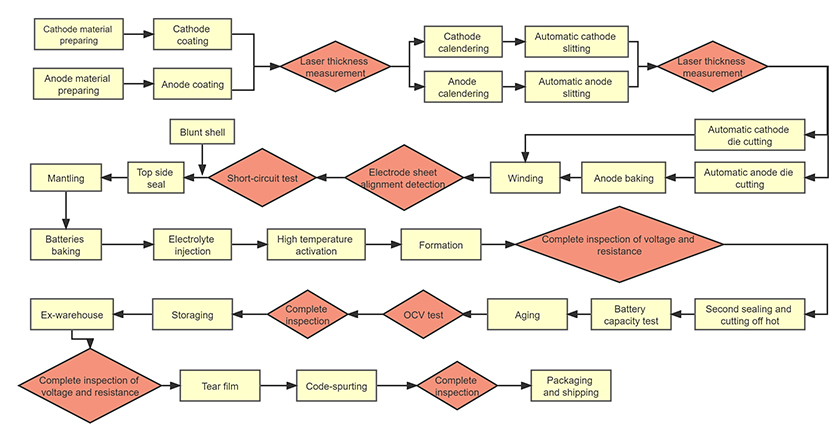

Detection process:

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat