It is mainly composed of ultrasonic generators, transducers, molds, pneumatic components, racks, etc. The working principle is that the transducer transforms the ultrasonic frequency high-power oscillation signal into mechanical energy of the corresponding frequency, and applies it to the interface of the metal sheets to be welded, so that the joints of the metal sheets generate heat instantly, and then start the particles in the metal lattice. The molecules at the junction of the metal sheets penetrate each other and fuse together.

Equipment function module:

This product is used for welding between aluminum foil and aluminum tab, copper foil and copper nickel or nickel tab;

The tab welding direction is horizontal, and the service life of the welding surface is ≥100,000 times;

Welding head standard, the welding head material is imported powder alloy, the height of welding point is 0~50mm, the upper welding head is straight or rice pattern, the upper welding head is mesh pattern; the distance of welding surface and welding place is adjustable of 0~50mm, welding head can two use welding surface;

The transducer can withstand power of 4000W;

The built-in frequency of the ultrasonic generator is adjustable, the switching power supply is constant voltage and constant current (constant amplitude), and the amplitude is steplessly adjustable.

Equipment performance characteristics:

1, Using advanced constant current and constant voltage circuit technology, the ultrasonic amplitude is continuously adjustable.

2, It adopts intelligent ICS chassis control system with secondary ultrasonic function; the system starts with self-inspection, the vibration pair is intelligently segmented and automatically tracked;

3, The mechanical structure of the machine head adopts the German X guide rail structure with high precision.

4, Protection system: ⑴ voltage protection system (the range of power supply voltage is 220V ~ 250V); the output power and operating frequency of the machine will not be affected during the period of automatic voltage leveling; ⑵ overload protection system; ⑶ over-current protection; ⑷ automatic compensation for power supply frequency instability ; (5) Welding overload protection signal feedback.

New Xinhui Automation was founded in 2005, currently has two production bases in Huizhou and Jiangsu, and can achieve an annual output of 1500 sets of high-end intelligent equipment for lithium batteries.

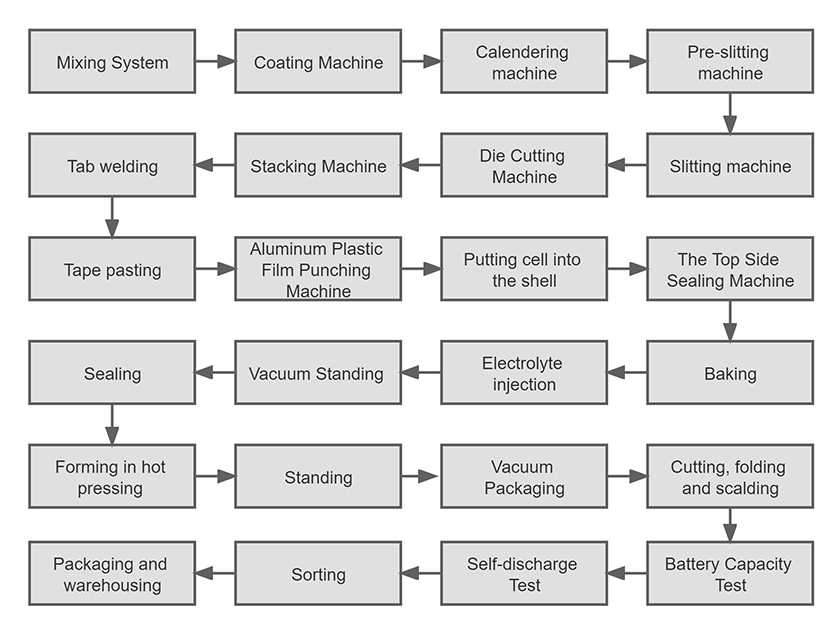

New Xinhui Automation integrates R&D, design, manufacturing, sales and service of lithium battery automation production equipment, and has created a full line of production equipment and module PACK automatic production line of lithium ion battery series such as cylinder cel l, pouch cell and square cell.

In recent years, New Xinhui Automation has passed ISO9001 quality management system, national high-tech enterprise, Guangdong Province specialized and special new small and medium-sized enterprise, specialized and special new small giant enterprise certification. Up to now, New Xinhui Automation has more than 100 authorized patents and software copyright.

Committed to becoming the world's outstanding lithium-ion intelligent manufacturing equipment supplier, New Xinhui Automation always adhere to the "customer first, win-win cooperation" business philosophy, adhere to technological innovation, constantly improve product quality, improve customer service quality, help customers improve quality, reduce cost and increase efficiency, empower the global new energy intelligent manufacturing.

Contact: Brady Sun

Phone: +86-18688347082

E-mail: brady.s@newxinhui.com

Whatsapp:+86-18688347082

Add: No. 10, Meihua Avenue, Economic Development Zone, Xuyi County, Jiangsu Province, China

We chat